Boric acid

Boric acid is in a dissolved form during the liquid phase of filtration and is separated from its by-products, chiefly calcium sulphate. To isolate quantities of the acid, the filter elements need to enable highly efficient cake washing.

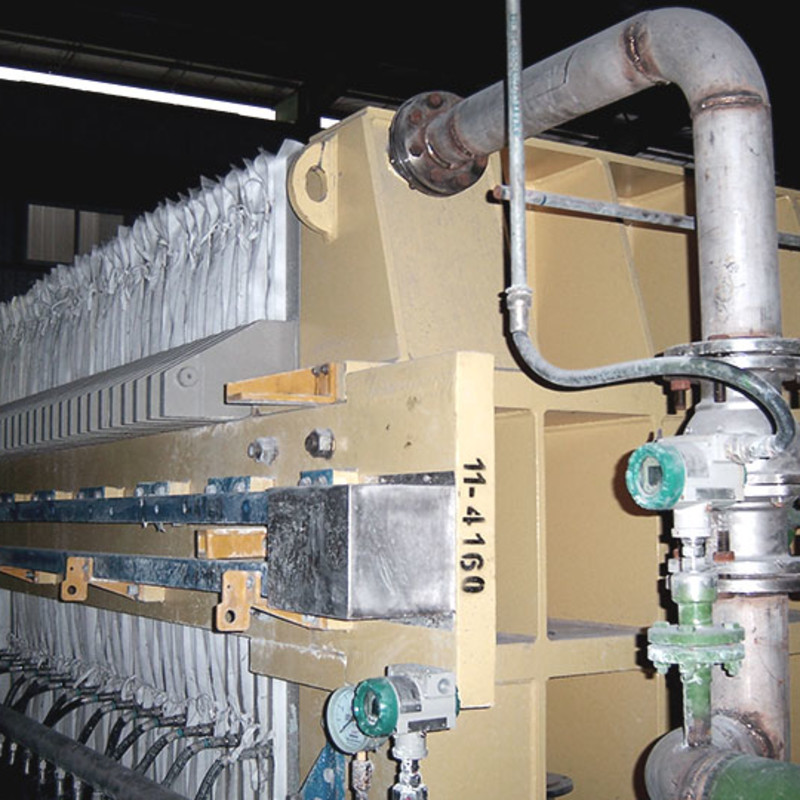

Filter elements used in the chemicals industry must be able to meet a range of chemical resistance levels as well as extreme filtration parameters. A multifunctional membrane plate is therefore required. Extensive know-how acquired through detailed research and development and years of proven experience are evident in Klinkau's range of membrane plates. The filtration of chemicals at temperatures ranging from -10°C to 95°C requires carefully selected materials to ensure stability and resistance. Wash processes within the chemicals industry are often complex so the plate design is decisive in achieving the necessary levels of washing efficiency. Klinkau's welded membrane filter plates in their standard and empty chamber versions are ideal for such tasks and have been delivering excellent results for many years.

Boric acid is in a dissolved form during the liquid phase of filtration and is separated from its by-products, chiefly calcium sulphate. To isolate quantities of the acid, the filter elements need to enable highly efficient cake washing.

Klinkau membrane filter plates are being used successfully at every stage of Tio2 production. Klinkau's replaceable overhang membrane plates have performed particularly well for the chemically aggressive washing of precipitated titanium dioxide. The ferrous sulphate found in the solution is washed out following filtration at temperatures of around 70°C and with a sulphuric acid concentration of up to 30%.

After Tio2 washing, welded or replaceable membrane filter plates in their empty chamber versions are then used for the chemically non-aggressive final filtration, as well as for coating and gypsum filtration.

The washed titanium dioxide undergoes dewatering at this stage of the process. To save energy in the downstream drum drier, efficient dewatering is required. The membrane plates are therefore capable of squeeze pressures of 30 bar and achieve far drier filter cake results than the standard squeeze pressures of 12 to 15 bar.

In this process, precipitated aluminium hydroxide is separated from the mother liquor. To produce an end product that is as pure as possible, extensive cake washing is required after filtration. Depending on the size and structure of the particles, washing is performed at 50 to 70°C in a single or multiple process. A membrane filter plate with a stayboss and corner feed is used for this process.

This application separates a vanadium salt solution from its by products. As in most chemical processes, the slurry contains mineral acids therefore requiring a highly resistant membrane. The quality of cake washing is vital to the profitability of the filtration process. After just 40 minutes of cake washing using minimal water, the dry filter cake contains only a maximum of 0.2% of vanadium oxide. These excellent washing results mean that even the silicate cake is also useable

Membrane filter presses are now being used worldwide for silicic acid processing. Klinkau membrane filter plates have all the features required for this process. Natrium sulphate is separated during filtration through the filtrate and then washed out through the silicate cake. Residual sulphate content within the cake can be set depending on the quality of the product and from 0.2% to 0.8% sulphate within the dry cake depending on the application. The special design of the membrane filter plate used here increases productivity and requires only a minimal amount of wash water. Klinkau membrane filter plates are used for a diverse range of silicate products such as filler material for car tyres, shoe soles, toothpaste, photographic paper and for applications in the pharmaceutical, cosmetic and food industries.

Membrane filter presses are being used for a diverse range of applications in zinc refineries, predominantly for lead and silver separation. The saturated zinc sulphate solution, containing up to 10% sulphuric acid, is filtered at temperatures ranging from 80 to 90°C and separated from the lead and silver residues. Cake washing then takes place to extract as much zinc sulphate as possible. Because of the chemically aggressive slurry, the membranes are made from modified polypropylene compounds.

To achieve the levels of purity required in zeolite production, the highly alkaline products are extracted in a complex process of cake washing. Specially designed plates enable only mildly heated water to be used thereby saving on energy costs. The chemical resistance of the materials used in the membrane construction is important to cope with filtration temperatures ranging from 70 to 80°C and the high levels of alkaline content within the slurry.

Extremely diverse process parameters are required for the production of azo, dispersion and reactive dyes. Membrane filter plates have proven themselves over many years in all three areas of dye production. Excellent cake washing requirements are the basis for the plate's design. Filtration temperatures range from room to 90°C. The membrane filter plates also need to be resistant to highly concentrated acids as well as alkalines. The slurries often contain residual aromatic substances, solvents and technical alcohols. Such extreme conditions place high demands on the choice of plate design and material.