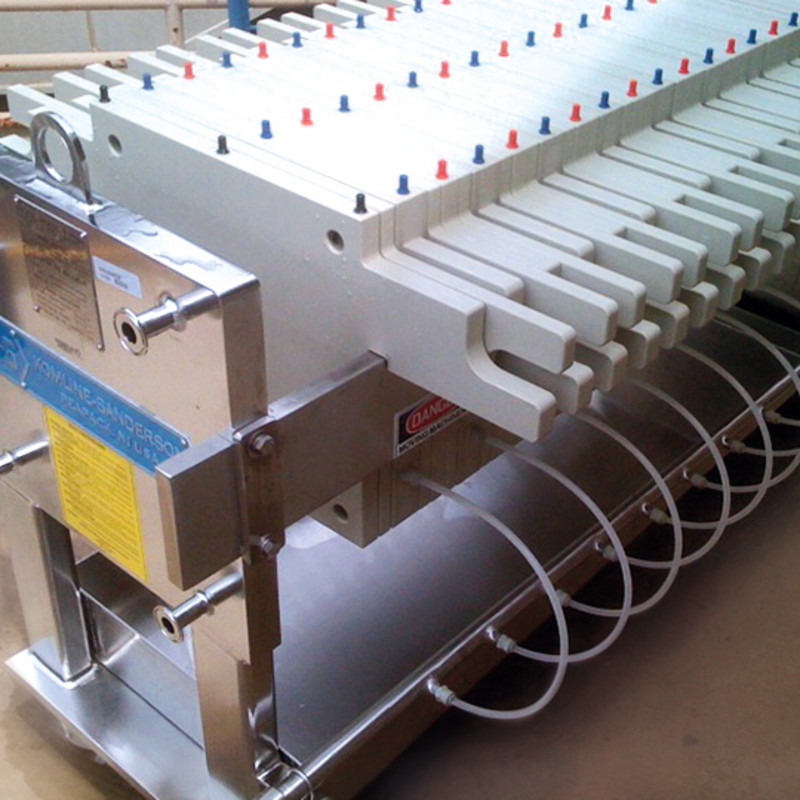

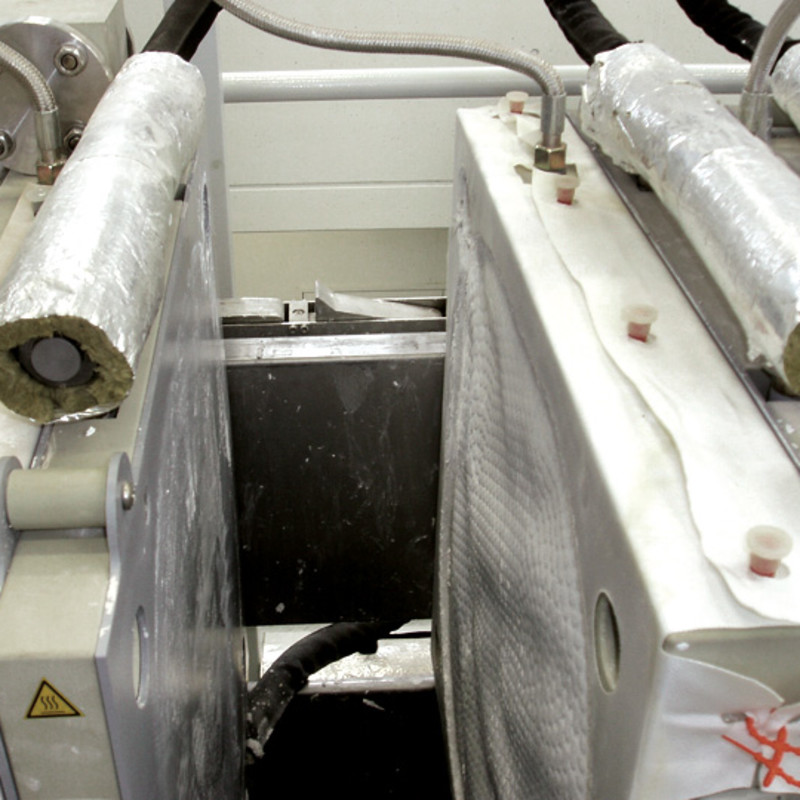

TCD thermal cake drying

In many areas, solid substances are dewatered to the required TS content using thermal drying methods. This requires the handling and transportation of materials. Standard drying facilities incur high energy costs with energy wastage in inefficient systems. By using Klinkau heat exchanger plates in filter presses, filtration, squeezing and thermal drying all take place within a single unit. It is especially suited to the dewatering of hazardous slurries because any toxic emissions produced by drying are then kept to a minimum. Drying is performed within the filter press itself so transportation of the dewatered filtrate cake to a drying facility is unnecessary The TCD process also achieves significant savings on disposal costs because the high-level of drying (exceeding 90% if required) reduces the weight of the filter cake. Lower transport and storage costs are then the result.

The TCD procedure can also be used during filtration to produce extra dry filter cake.

Existing filter presses are easy to convert to the TCD system. All that is required is 2.5 bar of saturated steam which can be generated by mobile steam units when a mains steam supply is unavailable.