Klinkau provides all the support needed right from the planning phase. Following detailed process analysis, the filter elements required undergo geometric and constructive design and are correlated to the anticipated filtration parameters such as temperatures, pressures and mass flows. For the filtration of critical and corrosive mediums, suitable materials are tested using actual slurries.

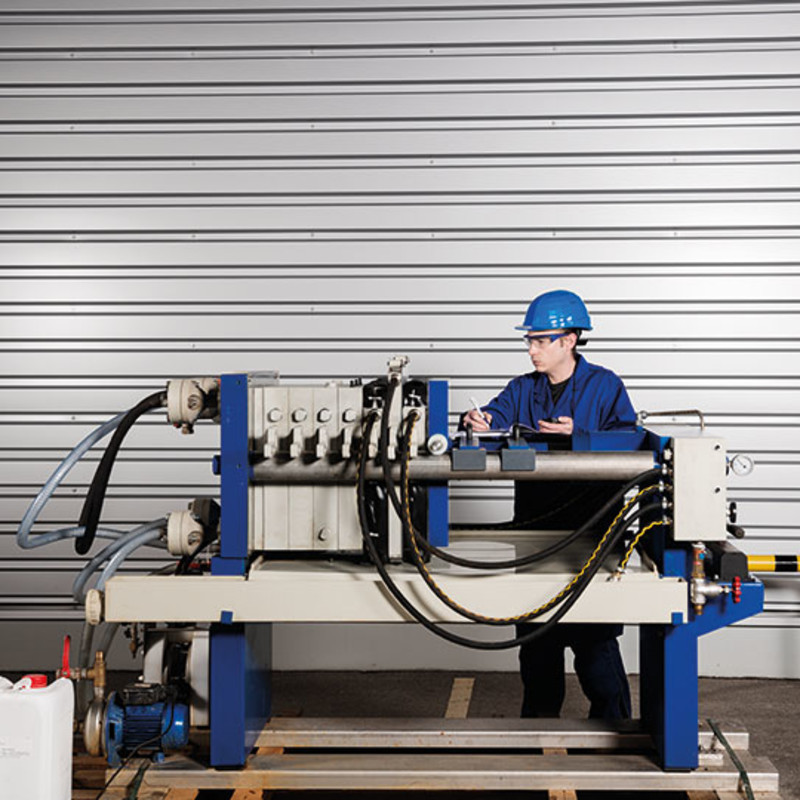

Filtration is then tested in the laboratory or, when necessary, in a mobile pilot unit to help determine optimal filtration parameters and mass flows. This then ensures the subsequent filter presses are correctly equipped as well as peripheral equipment such as pumps for filling, washing and squeezing, press pipework, valves and press instrumentation.

Service

Service

Klinkau has more than 30 years of experience in the filtration sector and has offerings that go far beyond the production and sale of filter elements.

Klinkau can also provide personnel, if required, to support the customer on-site with press installation and start-up. Klinkau offers training, especially for maintenance and production personnel, once the filter press is operational. For existing filter presses that use filter elements from competitor firms, Klinkau remains the right partner to rectify processing problems, replace non-functioning filter elements, or to upgrade poorly functioning filter elements.